DIY solid wood table and bench 2022

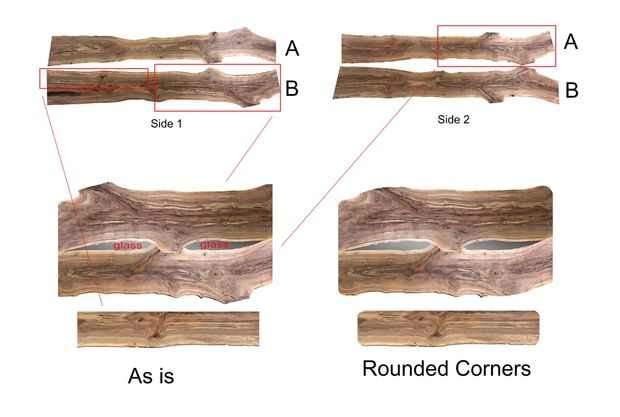

A bespoke walnut board dining set with uncut edges, LED lighting, glass inserts and metal legs.

Working on the table was a lot of fun. My client’s order was special (and interesting). And as an incentive — the budget. Her request included the following items:

- Worktop with unedged edges on both sides, consisting of two separate walnut boards.

- Lots of patterns and contrast.

- Cavities in the middle for a collection of agates.

- To illuminate the agates, there should be LED lighting in the cavity.

- The cavities are covered with removable glass inserts.

- Table top measures 100 cm wide and 210 cm long.

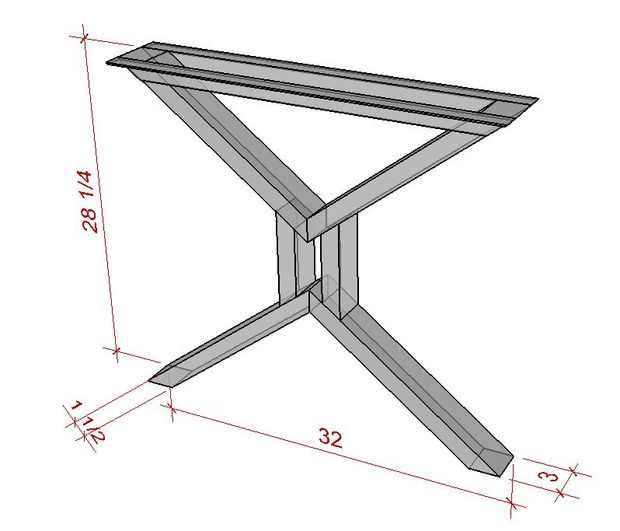

- Bespoke steel legs (blackened).

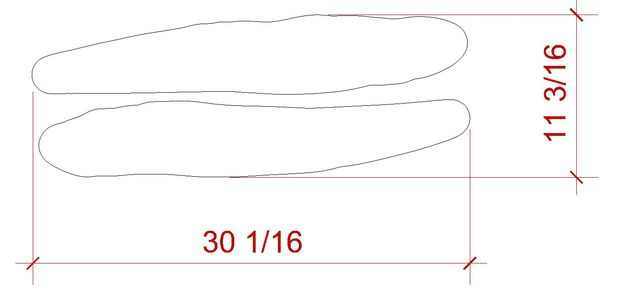

- One bench in a similar style.

- Production time no more than a month.

I tried to document every step of the process, but the deadlines were pretty tight and sometimes I didn’t get a chance to take a photo. Sorry for the missing photos; I will try to describe these steps in more detail…

Material search

I do not consider this stage the main one, but it can last quite a long time. Much of the time, energy and gasoline was spent visiting various sawmills and wood yards in search of suitable material. It seemed like a feat, given the established width requirements. I had to find two boards with raw edges, and putting them side by side, the total width should be the required 100 cm. Their shape had to form voids to accommodate the customer’s collection of agates. Boards should have characteristic pronounced patterns. There were also standard requirements: the boards were dried in an oven or for a couple of years in the air, they have a pleasant appearance, a plane without unnecessary twists, warping, notches (everything that would require removing the layer in thickness). And, of course, the cost should be reasonable.

The search usually starts with e-ad sites in the «building materials» section. Often, local craftsmen put up extra boards for sale at reasonable prices. Shops can also place ads in an attempt to attract more customers in this way. I found a few decent options nearby, but there was nothing that fit the bill. After that, I stopped by some of the local lumberjacks who saw the logs into boards. These guys often have their own sawmills and sell the board for a good price because the logs they get are cheap or free and the quality isn’t always the best. But that didn’t work either, so I had to move on to stores and warehouses. Obviously, there is already a choice here, but at a very high price.

I finally found what I needed at the local store. Not really in a store. It turned out that its owner has his own sawmill and a warehouse full of boards with unedged edges. He had several stacks of nuts to choose from. Here I found what I was looking for. The boards were the perfect width, sawn from the same log (symmetrical), dried in the right conditions for 3 years, nice and flat, and the price was relatively inexpensive. They came with a bonus. Since they were processed with a wide planer, I did not need to eliminate the uneven sawn surface by grinding. I don’t have a planer 60 cm wide…

During the search, I sent photos to the client to get her approval. We both opted for these two. Finally, it was time to move on to the next phase of the project!

Design development and approval

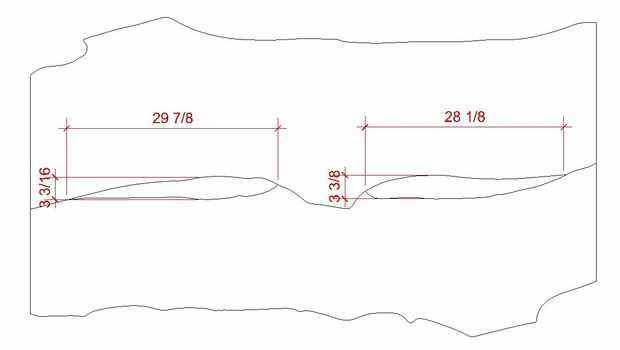

Before taking on a tool, almost every project I start with is a computer-aided design (CAD) design. With raw edges, this is a little more difficult to do, since it is difficult to repeat them in CAD. I solved the problem by putting up a high ladder and taking a photo of the boards along the entire length. Then I imported the pictures into the program and outlined the contours. A measuring tape was visible in the photo to more accurately scale the graphics.

After designing electronic models, I superimposed a real shot of the surface of the boards on them, so that it would be easier for the customer to imagine what I was going to do. After we decided on the design, I designed the different elements, how they would interact and attach to each other.

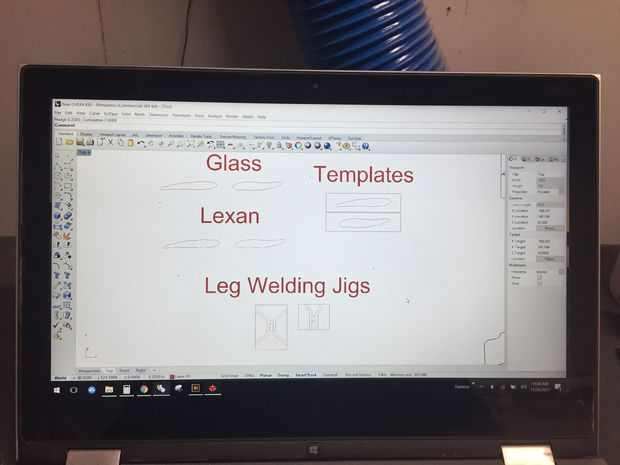

For this project, I vector-drawn different projections of the model for all sorts of purposes. I drew the outlines of the central cavities and exported them to a DXF file, which I then sent to the glass company to have them cut out the same shapes for me. I used the same file to make a template with an outline of the cavity, on which you can cut polycarbonate plates that will be attached to the underside of the tabletop. I cut the templates and polycarbonate on my homemade CNC router. I also cut out a template for fixing parts of the metal legs in order to weld them correctly. I even laser cut the profiles of various metal parts, which will help me cut the leg parts at the right angle. Having designed a complete model in CAD, you can start working, or at least it will be much easier to work with.

Preparation of boards (puttying cracks, fixing knots, grinding)

In most cases, I like it when all the knots, cracks, voids are fixed and filled with black epoxy, especially when working with walnut. Black color most often looks natural, and sometimes gives contrast. Since the boards had quite deep cracks here and there, I used a resin with a long curing time; this will allow it to soak in well and help to really fix the cracks rather than create the illusion of filling. The downside to this method is that you almost always have to reapply the resin a second, and sometimes even a third time. Sometimes I use a resin with a fast curing time for reworking. I filled in all the gaps on both sides of the boards so that they can be fixed securely. It is better to apply epoxy resin with a “hill” so that bubbles do not appear during grinding (so they rise above the plane of the board).

After filling all the voids, I sanded the exposed parts of the epoxy with P60 grit.

Shaping at joints

Unfortunately, I didn’t document this step very well. Essentially, I laid one board on top of another in the desired position, and marked out the area to be removed. Directly for work, I used a jigsaw, an angle grinder (with a milling disc and a flap disc), and, where necessary, hand tools for woodcarving. There was a lot of fine work and fitting at this stage. Along the entire length between the boards, I left a seam about 4 millimeters thick. I thought that the table would look more expressive this way. On the downside, the seamless fit leaves corners that don’t look good. The thickness of the seam will be maintained thanks to the dovetail key. I then leveled the edges of the table with a circular saw.

During this step, I scraped the raw edges of the bark off both the table and the bench with a scraper. Then I went over them again with an angle grinder with a flap disc to make the uncut edges smoother.

In the bench, I cut off one raw side with a circular saw. I agreed with the customer that one side of the bench would be straight.

Connecting boards with dowels and dowels

I used dowels to connect the central parts. They serve to fix two boards in the same plane (in relation to each other). The dowels and legs of the table will bear the main burden of fixing the tabletop. Unlike the dowels that I happened to meet, I made these with a thickness almost equal to the thickness of the boards.

The key material was made by gluing a walnut leaf between two mahogany sheets and CNC cutting the shape. I also made a template that will help you cut the grooves for the key with a hand router.

After leveling the seam between the boards, I fixed them to the table with clamps. Then, using the template, I cut out the grooves with a router. Where the router left the groove rounded, I had to work with a chisel. I could do a dovetail with rounding, but I like the look of even corners.

Once the keyways were ready, I carefully tried inserting the dovetail (to make sure it didn’t get stuck!) and started gluing. The dowels were made a little thicker than the grooves, so they were sanded flush with the table top.

After this step was completed, I sanded all the surfaces going from P60 grit to P180 grit. The final sanding with P220 grit was carried out immediately before polishing.

Insert glass, polycarbonate and LED lighting

I used the CAD model to create the inserts for the glass and polycarbonate plate. Double-sided tape is perfect for temporarily fixing workpieces on the surface of the table. Then I used the hand router again to create grooves on both sides of the boards. For more precise work, I used a chisel and a chisel until the glass lay flat and fixed without hesitation. The glass was removed and inserted many times, for this I used suction cups.

Polycarbonate sheet inserts were prepared with a CNC machine and a face mill. Here I had to make a decision on how to more securely fix the plastic inserts on the bottom of the countertop. I wanted them to be easy to remove, for example, for replacement due to scratches. I decided that walnut flags would be just right. So I cut them with a laser cutter from the material I had.

Before inserting the plastic, I had to deal with the LED backlight. For a more sophisticated effect, I decided to place LED lighting around the perimeter of the plastic. This technique will also help hide the wires. I purchased a thin LED strip with an adhesive side that can be easily glued to the indentation I made earlier around the bottom of the cavity. I had to assemble two separate electrical circuits in the form of a Y, which should then go into a separate dimmer. The dimmer is connected to the battery on one side and to the 12-volt power supply on the other. This allows the lamps to glow both from batteries and from the mains. The idea is for hosts to plug in the charger when they’re not using the desk, and to remove the wires when they get in the way. The wires and the battery were fixed to the bottom of the tabletop with clamps and anchors. I considered the option of embedding the battery and wires in a tree, but finally decided that it was better not to, since all these components would someday have to be replaced. In the end, this table should become a family heirloom that will outlive me, the customer, and the LED lights. They say that LED lamps can last quite a long time, but if the desire arises, they can be replaced with something similar.

After trying on the plastic and checking the operation of the lighting, I put the plates aside. Locking flags and plastic can be attached after polishing.

Polishing

The customer wanted to use a polishing material that would preserve the natural look of the wood, make it durable, but not look like varnish. So I settled on OSMO PolyX. This product is conceived for wooden floors, but it is also suitable for furniture. It has a low content of volatile organic substances, and a high content of solids, since it mainly consists of wax and natural oils. It’s easy to apply. Two layers are enough to achieve a good result.

I didn’t take pictures of this process, because I always had rubber gloves smeared with polishing paste. Before applying the layers, I went over the surfaces and edges again with P220 grit.

To apply OSMO evenly to the surface, I used a spatula. It was easy for them to completely moisten the wood and cover all the small irregularities with the paste. On the edges I had to use fabric. After moistening, I removed the remaining paste with a lint-free cloth. At this stage, it is important to work out the surfaces well, but completely remove the excess. I covered the top, bottom, and all edges of the table and bench, and let them dry for a day or two, then did it all over again. Only two coats are enough, and in fact, applying more can lead to an undesirable glossy effect.

As a result, the processing of the wooden parts was completed, I laid the polycarbonate plates in their places and secured them with flag clamps.

Creation of legs and their installation

The legs were made from a rectangular steel pipe measuring 3.8 x 7.6 cm and a 3.8 x 3.8 cm iron corner. To make the process easier, I cut out templates with a laser cutter to fix the necessary components and the workpiece, which will help to fold everything at the right angle. A long time ago I was an excellent welder, but as the years went by and without enough practice I still had functional skills, but I forgot how to weld with decorative seams. To make up for this shortcoming, I used an angle grinder to grind off the excess metal and give the surface a neater look.

Upon completion of the welding work, I processed all the metal surfaces with an angle grinder with a flap disc so that they had a uniform texture and shine. In the corner metal, I cut oblong holes for attaching the tabletop so that if the wood shrinks or expands, there will be no problems. I welded the lower parts of the legs with iron plates, so that later I could drill holes in them and install a height adjustment mechanism.

The customer wanted the legs to be black. We thought a little about how best to do this. Instead of paint, we decided to use a steel burnishing agent, so the result will be more durable and hide imperfections better. I used a product called presto black. The application was carried out through a spray until all surfaces were covered with a substance, and then its effect was neutralized with a solution of baking soda so that the metal did not begin to oxidize (rust). After removing the bluing agent, I dried the metal with a compressor, and coated the surface with matte polyurethane to keep it from rusting along the way.

To attach the legs, I used furniture nuts and bolts, which will allow you to remove and install the legs again and again. I fixed the legs in the bench with large wood screws, since it is not large and can be moved without removing the legs.

Delivery and installation

The customer lives three hours away from me, so when transporting the table, it was important to pack it properly. I removed the legs from the bench and table, wrapped each component separately and sealed it in plastic wrapping material. It’s important to wrap and pack the parts in the order you took them apart because they will be in the right place when you put them back together. It will be easier. For example, when I drove to the house where the client lived, the first thing I had to unload from the van was the countertop. I placed it in the house upside down on the floor. The next parts available were the legs, which I attached to the table top. Then a bench, bench legs and so on. It may seem like common sense, but if you get carried away with packing, you can easily forget about everything. I didn’t film this process, but I’m sure it’s pretty easy to imagine.

The customer liked the dining set very much, and now her collection of agates lies in the illuminated recesses, in the middle there is a bouquet according to the season, and around it is a specially selected set of chairs. It is in the photo. A table can spice up an already cute space. I am glad that this creation will end up in a beautiful home where it will be admired and taken care of.

Thanks for attention!