The content of the article «what is a tape foundation»

A high-quality foundation is the basis of the entire concept of a future house or other structure. The integrity of the entire structure depends on the correct choice of the type of foundation, its correct calculation and arrangement. All physical load from supporting structures, walls, floors and roofs falls on the base and should be evenly distributed over the area, in order to avoid damage: the appearance of cracks and wall destruction due to soil subsidence or deformation of the foundation itself.

There are many types of foundations. Depending on the moisture conditions of the soil, the proximity of trees, soil types, physical activity, its future shape is determined and projected. And one of the most versatile options is the arrangement of the strip foundation.

WHAT IS TAPE FOUNDATION?

Strip foundations are a concrete structure that runs around the perimeter of the house. These foundations are built under all load-bearing walls of the structure, maintaining the integrity of the house structure and efficiently distributing loads over the entire area. The technology for building the foundation is relatively simple in comparison with other types, including pile-screw, but it requires a lot of time, materials and efforts to implement the project.

The strip foundation is effectively used for:

- Houses with concrete, stone, brick walls (with a density of more than 1000-1300 kg / m3);

- Buildings with massive and heavy materials (monolithic or prefabricated reinforced concrete, metal, cinder block);

- When it is necessary to arrange the basement floor or, since the tape base simultaneously performs two functions — the foundation and the walls.

WHAT IS A TAPE FOUNDATION 2022

STAGES OF CONSTRUCTION

If it is necessary to erect a strip foundation, follow a certain sequence of actions to select the correct depth, width and base materials.

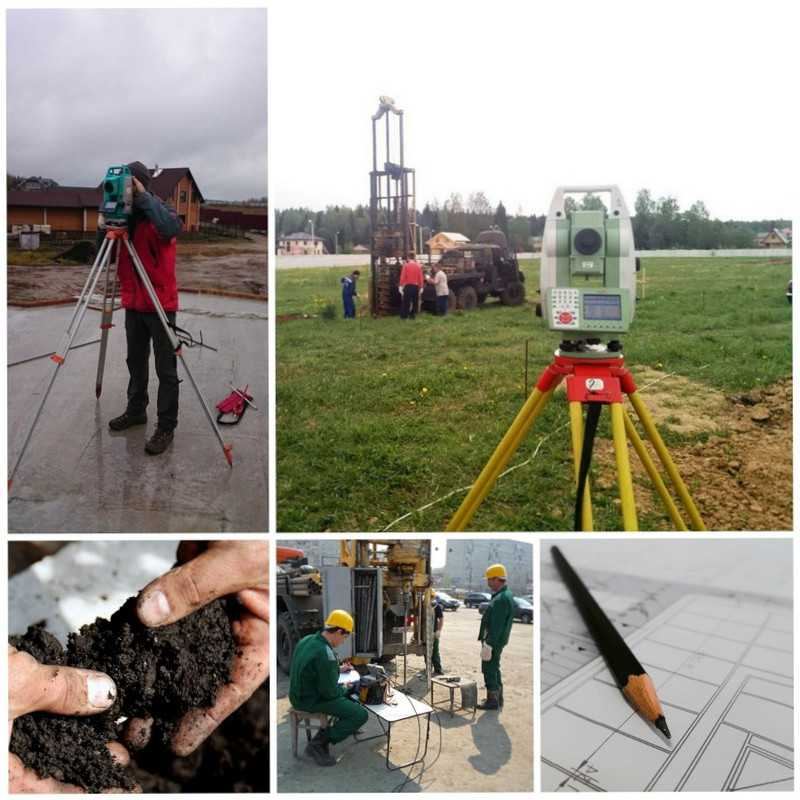

ENGINEERING SURVEY

The first step is to carry out a full range of engineering and geodetic surveys. It is necessary to understand the type of soil, its moisture content (it may be necessary to arrange an additional drainage system to drain groundwater). It is also important to measure the level of the surface of the land plot, since with a difference in elevation, it will be necessary to erect a stepped strip foundation.

Engineering and geological surveys

Important! With an uneven surface and the need to arrange a stepped foundation, the calculation and its direct arrangement takes place, starting from the lowest section.

To check the composition of the soil and its moisture, a special well is made, at least 50 centimeters deep more than the depth of laying the future foundation. This will make it possible to qualitatively determine the constituents of the soil and take into account the possible expansion of the soil in the winter, when the moisture freezes, which contributes to the rise in the soil level. This data is important for the correct calculation of the strip foundation.

Further, the design documentation is drawn up, which takes into account not only the architectural features, but also calculates the mass loads of the future structure, including the floors and the roof. This affects the width and depth of the required foundation.

Important! Only highly qualified civil engineers can correctly calculate the necessary parameters of the strip foundation based on the design of the house. Failure to comply with established norms and standards leads to violations of the integrity of the structure and destruction of the foundation.

PREPARATORY WORK

Before starting the implementation of the project for arranging the strip foundation, it is necessary to carry out a set of works to prepare the site:

- Cleaning the site from stones, debris and other objects.

- Uprooting trees, shrubs.

- Leveling the surface of the land.

In general, before the marking procedure, the land plot must be flat and free of bulky objects and trees and tall grass.

Installation of the strip foundation

MARKING

The marking of the future strip foundation takes place in strict accordance with the data in the design documentation. The angle of the foundation will be determined, set the stake and pull on a special mounting rope or ordinary thick fishing line. Starting from the corner, the distance is measured and pegs are mounted along the entire length of the foundation and the fishing line is stretched, both from the inner and outer walls of the base., After which work begins on the arrangement of the formwork and the installation of reinforcement.

TRANCH, FORMWORK AND VALVES

First of all, according to the established markings, a trench of a given depth and width is being dug. This can be done efficiently with special equipment or manually. When the trench is ready, the bottom is filled with a sandy base supplemented with gravel.

Facing formwork is made of 40-50 mm planed boards or plywood sheets. During the installation of the formwork, its verticality is constantly monitored. You can check this through the building level.

The next step is to strengthen the foundation. Reinforcing rods with a section of 10-12 mm are connected with a specially designed wire, so that the sides of the square cells are 40-60 centimeters. Reinforcement bars are made of steel or fiberglass. When placing reinforcement in a trench, it is necessary to observe the indents from the edges. The optimum filling is 50 mm. In this case, the reinforcing base will be most effectively located in the strip foundation monolith.

Shallow strip foundation

Digging a trench

FILLING WITH CONCRETE

Preparation of concrete: cement is mixed with sifted river sand in ratios of 1: 2 — 1: 2.5 and diluted with water to the consistency of a liquid cream, after which it is poured onto prepared gravel, into trenches lined with formwork with installed reinforcing reinforcements. The amount of crushed stone corresponds to the amount of sand. If we take into account the full composition of the solution for making concrete, then the ratio of the main components: crushed stone, sand and cement is equal to 3: 3: 1, respectively.

Important! When answering the question of what kind of concrete is needed for a strip foundation, it is worth considering its preparation from cement of grades M-200, M-300 or M-400 and depends on weather conditions and loads on the base.

The concrete mass should be poured evenly or in layers, constantly tapping the walls of the formwork to ensure its full distribution. For the same purpose, the surface of the poured mixture is compacted and leveled with a wooden spatula.

The entire formwork should be filled with concrete to the specified height, and the mass should be poured as quickly as possible to prevent delamination of the entire base.

Pouring concrete formwork

Important! You should think in advance about the need for the arrangement of engineering communications: water supply, sewerage and others. If necessary, even before the concrete is poured, special channels are installed for the future laying of communication systems.

WATERPROOFING AND BACKFILLING

A week after pouring, and by this time the concrete foundation will gain up to 70 percent of its strength, work on waterproofing begins. This is done through the use of special waterproofing materials or polyvinyl chloride (PVC) films.

Backfilling of voids formed after dismantling the formwork is also an important procedure that should definitely be followed. To achieve the optimum effect, sand is used, which must be carefully compacted.

Foundation waterproofing

Waterproofing strip foundation

HOW MUCH DIES A TAPE FOUNDATION

After pouring with concrete, the foundation is covered with burlap or other insulating material and left to dry for a period of several weeks to a month. Particular attention is paid to the surface of the foundation in dry and hot weather — moistening it to prevent cracking.

ASSEMBLY TAPE FOUNDATIONS

Prefabricated foundations made of bricks, gas or cinder blocks are a type of strip foundations. Prefabricated wall foundations and are composed of rectangular or trapezoidal blocks. They are stacked in a ranked formation on a sifted layer of sand, 10-20 centimeters thick.

Prefabricated foundations are not so widespread, due to the complexity of project implementation, high cost and low structural strength, which makes them suitable only for small buildings.

Prefabricated strip foundation device

ADVANTAGES AND DISADVANTAGES OF TAPE FOUNDATIONS

The main advantages of the strip foundation:

- Construction speed.

- Low labor intensity.

- Relatively low cost.

- Structural strength.

Disadvantages of strip foundations:

- Large mass of the foundation.

- The need for engineering and geodetic surveys.